UNIQUE TECHNOLOGY: The design and manufacture of Corbin products is so unique that Mike Corbin himself holds more than 60 United States Patents! From the process itself to new innovations like the Corbin Glovebox, you can count on highly functional and unique products that work.

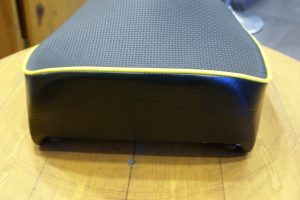

FIBERTECH™ BASEPAN: A purpose built, hybrid material that provides a firm foundation to support the carefully designed ergonomics of the Corbin saddle. Provides a precision fit to every arc and contour of the machine and rides on rubber bumpers to protect your paint. We always design our basepans as flat as possible so bumps or odd shapes don’t telegraph through the foam to your body.

One of the first things you’ll notice about your new Corbin saddle is how stocky it feels. Our high density foam and rigid Fibertech base material add some heft to the seat, but it’s worth it in the long run for sure! Here’s why:

Corbin’s basepan material is extremely stiff and therefore supplies the necessary rigid foundation to support the carefully designed ergonomics of the saddle. A thinner or more flexible base (ie nylon) would allow the saddle to sag in the middle which changes the foam shape impacting comfort value. We always design our basepans as flat as possible since odd shapes or bumps can telegraph through the foam and create pressure points.

Specifically designed for Corbin, this hybrid material has almost no shrinkage as it cures. Fibertech combined with our patented manufacturing process provides a precision fit to all areas of the bike and offers minimal manufacturing tolerance. The entire basepan only contacts your bike through rubber bumpers to protect your paint.

COMFORT CELL® FOAM: The heart of the Corbin saddle! Our exclusive, purpose built foam material, called Comfort Cell, was created to provide a firm, resilient ride that doesn’t break down. This means it will support you for long days on the road. Over time, Comfort Cell will break in to provide a personalized fit to your posture and even greater comfort!

ERGONOMIC SHAPING: A major part of the design criteria of the Corbin saddle is the Ergonomic shape. This means the saddle’s foam shape is designed to emulate the curves of the human body. This provides more square inches of body contact and helps to eliminate hot spots. This shaping also neutralizes the seating platform to help curb sliding in the saddle which reduces fatigue. In a nutshell… more comfort for a longer ride!

Better weight distribution: “ergonomic” is the applied science of equipment design intended to reduce operator fatigue and discomfort. Also called biotechnology, human engineering or human factors engineering. What it means is that the product was designed to work with the human body. This is a key factor in how a Corbin saddle functions.

Notice how our saddles are sculpted and shaped to fit the human body? That’s what we’re talking about. This gives more square inches of body contact which disperses your weight over a greater area. Since it matches the curve of your body, it also eliminates hot spots and centralized pressure on your spine.

In order to manufacture seats this way, it requires special materials and manufacturing processes. Over the years we’ve experimented with many different materials, but in the end wound up developing our own. The process itself, called Integrated Molding, was also invented by Mike Corbin and was awarded a United States patent.

Naturally we’re always on the lookout for new materials and processes. What you find today is the product of nearly four decades of relentless product development. Because of this, Corbin Saddles are commonly considered the finest motorcycle seat in the world.

PATENTED MANUFACTURING TECHNOLOGY: Always an innovator, Mike Corbin invented Integrated Molding technology which is now the process by which all Corbin saddles are made. This process allows extremely tight tolerances and creates a chemical bond between the foam and base material.

One of the main reasons Corbin saddles have been so popular over the years is because the technology under the saddle’s cover is in constant development. New models and improved features require constant diligence on the part of the factory to assure each product lives up to the original design. Integrated molding was the missing link between design concepts and actual production.

In a nutshell we’ve taken the components of the saddle and combined (integrated) the molds into one unit. Brackets and backrest hardware is placed in the mold where the basepan is created around it. The mold itself dictates the shape of the base and placement of the hardware while creating a clean rounded edge in the exact same shape every time.

This same mold is then used to cast our infinite-ratio Comfort Cell foam into the ergonomic shape common to Corbin seats. This process takes place on a tight schedule while the Fibertech base material is still at a curing stage. This creates a chemical bond between base and foam that helps keep the crafted shape intact under heavy use.

Integrated Molding has created a process so consistant it gave our R&D team the freedom to design for a more precision fit. Extremely tight tolerances allow the seat shape to fit every arc and curve of your motorcycle like never before. It also enabled us to introduce a host of new features like Chrome V-Rails, fold down backrest hardware, heater inserts and our new Ovalbac model backrests.

GENUINE LEATHER: We use leather in all panels of the seat that contact your body. This provides a luxurious ride that breathes with your body. Leather will also break in along with the foam shape to support the personalized fit. Available in a wide range of textures and styles to suit your taste. For more information about leather seating just click away.

With few exceptions (seats for off-road bikes), we include genuine leather seating panels in all Corbin saddles. A natural product, leather provides a luxurious ride by allowing your body to breathe while in contact with the seat. Leather is also extremely durable so it will last in the harsh environment your bike is subjected to.

Genuine leather will also adapt with the foam shape to support the personalized fit after break in. This is why we recommend using vinyl instead of leather in the SIDE areas of your seat. Vinyl will “spring back” instead of stretching, so it will support the foam shape and stay looking new.

We have a wide range of specialty leathers & vinyls available for covering your Corbin saddle, but beware the Kid in a Candy Store syndrome. Most people that create wild seat cover designs end up unhappy with them over time and admit they went crazy just because they could. So even though we let you choose any materials you want for your seat, doesn’t mean you SHOULD… sometimes less is more.

Lastly, be sure to care for your leather properly with a quality conditioner like Corbin’s Saddle Cream. This will help it to resist the elements and stay water resistant and looking sharp longer. Over time you can expect your saddle to break in and develop its own unique character, just like your leather jacket or gloves.

Corbin has perfected the ergonomics for your Adventure bike. Our saddles offer you a more sculpted seating platform that conforms to the shape of your body for better support and greater square inches of body contact. Of course we build them up with our Comfort Cell foam for firm support that lasts all day and engineered in a removable, adjustable rider backrest. A touring quality ride for a hard working bike!

Notice how the shaping is designed to emulate the shape of your body. This gives excellent support for longer range. Our neutralized seating helps to curb sliding in the saddle which greatly reduces rider fatigue. Naturally we include genuine leather seating for a perch that breathes with your body and enhances comfort even further. We’ve designed to cover pattern to look great on all years and colors of the GS. Saddle comes standard with natural grain black leather seating with tasteful stitch pattern. Stitch pattern in seating area is optional on non-heated seats, but required for heated models.

Corbin’s model is also designed to work perfectly with your BMW paniers in the various configurations available. The model shown here includes our electric seat heaters built in and you can see the switch conveniently located under your leg. There are separate switches for rider or passenger heat in this design. Just flip the switch and the saddle will heat up and maintain temperature through an integrated controller. Installation is simple with an included pigtail that wires to your battery.

Corbin’s leather seating will perform well for many years and adapt with the foam shape during break in for a personalized fit. Over time it will develop its own unique character just like your leather jacket. Just be sure to care for it properly with a quality conditioner like Corbin’s Saddle Cream. Your new saddle will be your favorite investment for many years to come!

Designed to fit perfectly and look custom, our front saddle mounts in either of the two height positions. Fits perfect and provides a nice custom touch. Installs by using the bracket transferred from your OEM seat.