Z-Upgrade 2.0 (Vcore 3.x)

More info: https://hackaday.com/2018/11/13/mechanisms-lead-screws-and-ball-screws/

More info: https://hackaday.com/2018/11/13/mechanisms-lead-screws-and-ball-screws/

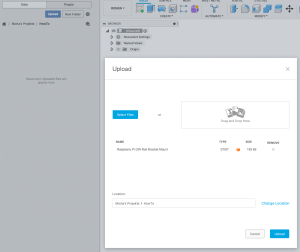

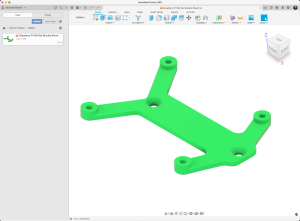

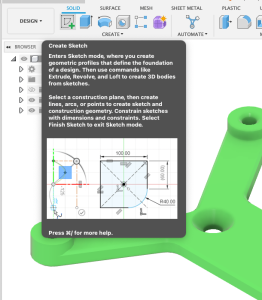

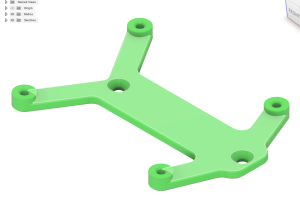

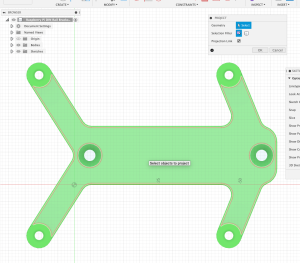

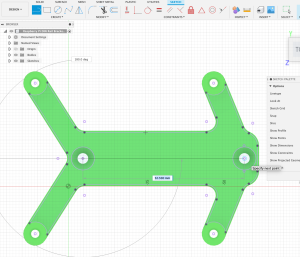

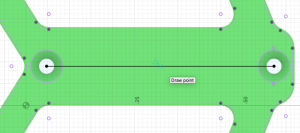

Get this file: https://www.printables.com/model/420062-raspberry-pi-mount-for-din-rail-bracket-fan-mount

Wanting to mount it however to this: https://aliexpress.com/item/1005002245769197.html

which has different mounting holes (47.5mm versus 52.5mm and, need to be for M4)

1.

The Bozzle nozzle is the very first high flow (and lower back pressure) tungsten carbide nozzle for 3D printing applications.

Tungsten carbide nozzles are capable of printing all 3D printing filaments due to their exceptional hardness, ultra high operating temperature and high thermal conductivity.

0.5mm orifice

No inserts – constructed out of a solid piece of tungsten carbide there are no inserts here

Non stick surface finish

Significantly increased layer to layer adhesion at same printing temperatures vs hardened steel nozzles

Compatible with V6 and MK8 hotend heatblock

This nozzle requires hot tightening. Install the nozzle, heat hotend to 20c over desired use, and hand tighten with a 6mm or 1/4″ socket.

This nozzle will print every material.

Single, dual or triple screw Z?

(Part 1)

You will probably notice that most high-end commercial printers use either single or dual lead screws (or ball screws) but seldom 3.

Single screw Z pros

With just a single Z screw there is the least chance of mechanical quarrel. Mechanical quarrel is when two mechanical forces oppose each other and in kinematic systems it usually leads to increased friction or binding if the systems don’t have some compliancy built in.

With a single linear motion system there is only one linear path that the bed should move in. Normally two large diameter heavy duty *smooth rods or a single very wide linear rail are used to create the vertical linear motion system. If two smooth rods are used a single piece bed arm (or cradle) bridges both smooth rods and the screw lifts in the centre of this arm.

A single piece non moving bridge is located at the bottom and often another is place at the top, providing a very rigid mounting structure for the smooth rods capable of overriding any lateral forces a bent lead screw might impart to the bed arm. The lead screw will typically be loosely constrained at one end.

This setup provides a precision of movement and helps produce high quality prints.

There is almost no chance of lead/ball screw induced artifacts.

Nice open access to the bed without obstruction from multiple linear motion systems.

Very simple system.

*In some rare instances two widely spaced linear rails may be used but dual linear rails abut to prevent binding dual linar rails need to be aligned in multiple planes. This normally requires a finely machined surface for both rails to sit on (expensive) or some compliancy need needs to be built in (sub optimal).

Single screw Z cons

Can’t do automatic bed levelling. Bed levelling must be manual.

As the bed is always cantilevered and there is only one bed arm. This bed arm must be sturdy. This generally necessitates it being machined from metal (expensive).

The vertical linear motion system is normally bespoke and the bed arm and supporting structures (for twin smooth rods) are machined from billet for rigidity and accuracy….and hence consequently expensive.

Heavy duty linear bearings are required as they need to cope with the angular loads of the cantilevered bed. All else being equal these bearings also need to be longer for this reason than bearings used on dual or triple screw Z motion systems.

As the bed is only supported on one side it must be thick enough not to flex…which makes in expensive and heavy.

Z movement speed is usually limited to stop the bed ‘flapping’. If you are using Z hop when printing to stop the nozzle dragging across the just printed layer this will increase print times more than you might initially expect.

Bed depth is normally limited, and it is common that the beds will be much wider than they are deep.

As only one screw is doing the lifting it needs to be heavier duty than a two or three screw system and is hence often a ball screw. Ball screws are more expensive than leadscrews.

Summary

A single screw Z motion system with a cantilevered bed is the simplest solution and works great for small bed sizes.

However, to do a cantilevered bed properly you need expensive components and typically a custom machine bed arm, but the reward is a precision motion system without mechanical quarrel or screw induced artifacts in the prints.

Single Z screw cantilevered bed systems are currently the most popular of the designs used in small format commercial printers.

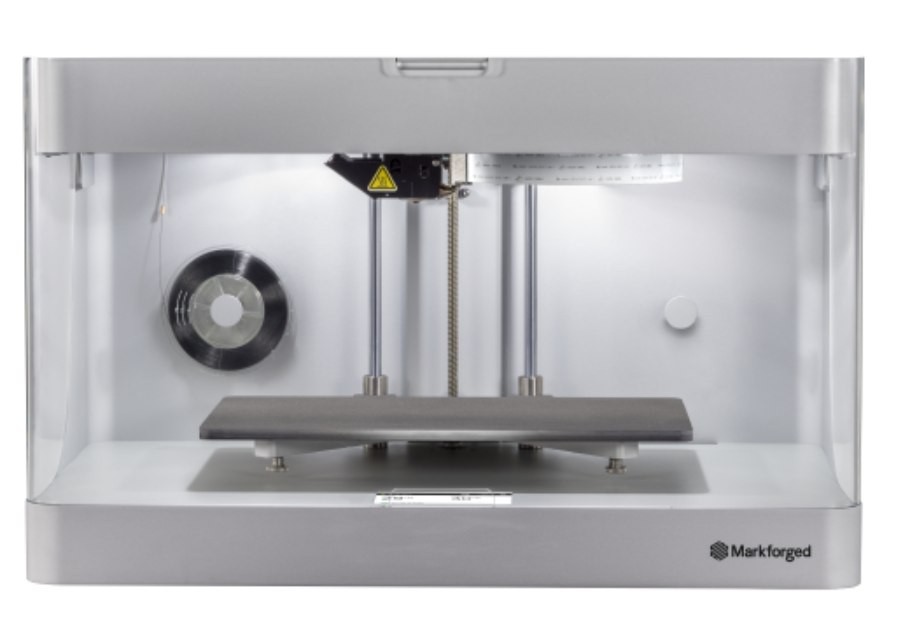

Example below is of a MarkForged printer which is has excellent kinematics and is capable of producing very high quality prints.often

I made an overview of all mods done to my Prusa Mini + ?

With lots of thanks to so many different people on Thingiverse and Printables

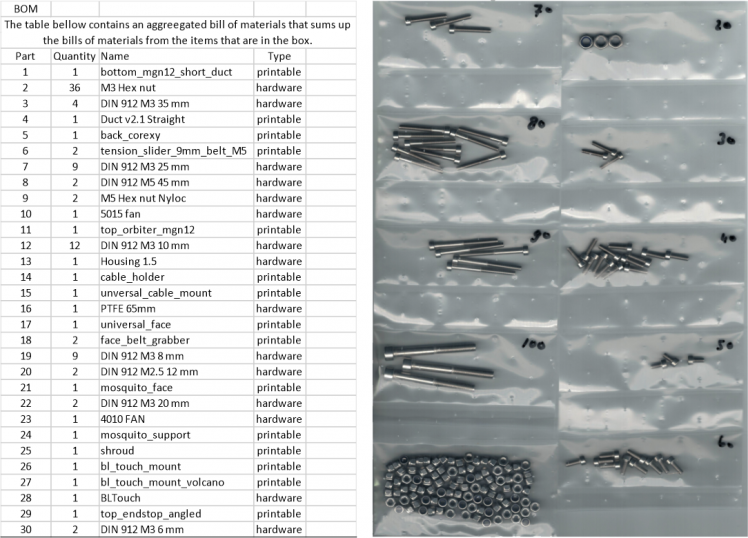

Prusa Mini+, mellow V6 alu cold block/heatsink, mellow brass heater block, mellow silicon heater block sock, E3D v6 Titanium heatbreak 1,75 mm (origineel), Bondtech CHT 0.4mm nozzle, LDO Orbiter 1.5 extruder, Weishuo 24V-10A-240W PSU, Raspberry Pi 3a, Argon1 FanHat, Raspberry Pi PSU 5.1V 2.5A MicroUSB, Prusa Stepper motor Z-axis, Misumi Linear bearings kit + superlube, AluX Bear mini 2040 extrusions, GT2x6 mm Kevlar-reinforced timing belt (2,5 meter), USB-USB-c kabel, wiring + plugs, printed parts, High Power MOSFET 30A, fans, PrintBay Heat bed insulation, buck converter

https://docs.mainsail.xyz/setup/

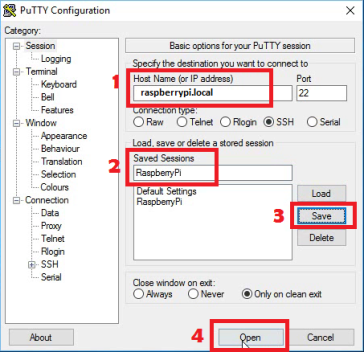

putty into your Raspberry Pi:

cd ~/klipper/

make menuconfig

Enable extra low-level configuration options

STMicroelectronics STM32

STM32F407

Bootloader offset to 128KiB + 512 byte offset

Clock Reference to 12 MHz crystal

Communication interface to USB (on PA11/PA12)

close and save

make

switch off mini (only)

put on pin over 2 prongs on pcb buddy board

switch on mini

sudo service klipper stop

make flash FLASH_DEVICE=0483:df11

sudo service klipper start

switch off mini (only)

take off pin over 2 prongs on pcb buddy board

switch on mini

restart firmware in mainsail

https://www.esun3d.com/eclean-product/

Modelnummer CLN175N01KG/ CLEAN175MM

EAN 0781520911112/ 6922572242418

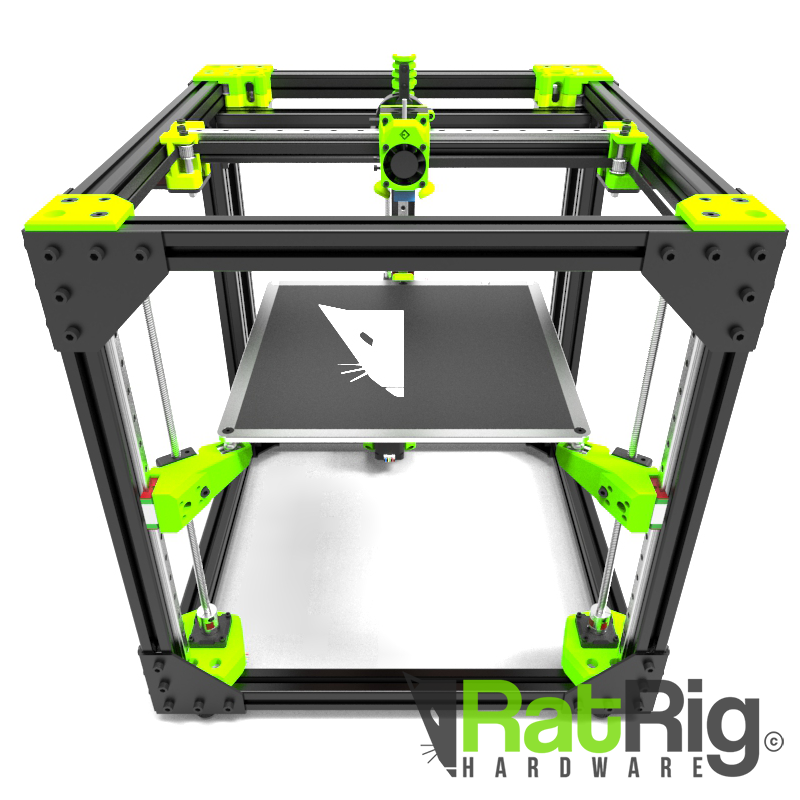

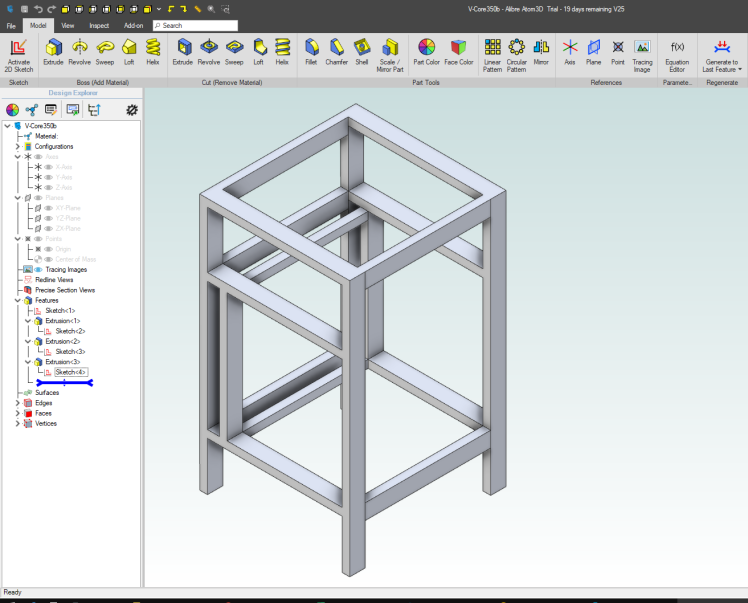

today, I finished the main modification of the printer (I only want to change the wires soon) so the whole frame is changed, the hot-end, extruder, heatbreak and nozzle, and all printed parts were PETG are now ASA, instead of a Cantilever design it is now an H-frame with double Z axles, so the frame gives rigidity and structure to the printing, yet still running the original Prusa firmware (with some added G-codes)

Source: https://www.bondtech.se/2021/03/12/a-diy-solution-for-prusa-mini-ptfe-replacement/

and https://www.facebook.com/groups/prusaminiusers/

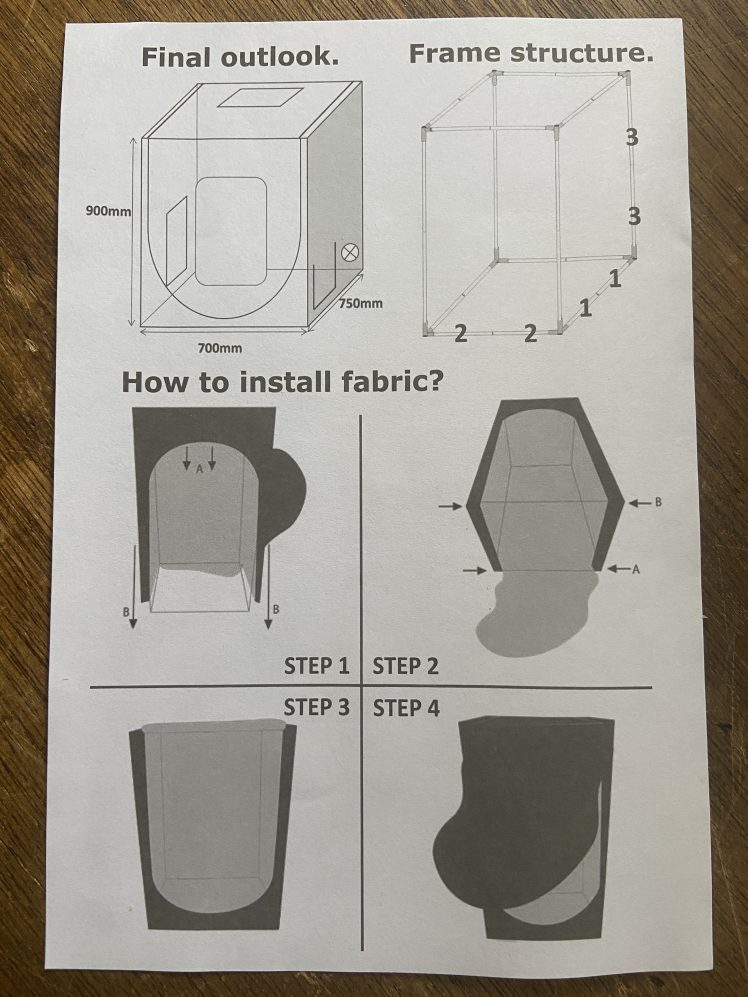

all self-drilled/tapped hidden joints and external doors with magnet/metal strips and printed hinges and handles. 2020 extrusions with 3mm plexiglass side panels and 6mm dibond floor panel

“–Don’t leave your lover until you have another lover; don’t leave your job until you have another job.” – Ra Uru Hu

Same is true for 3D printers… don’t sell your 3D printer when the new one has a 5 week waiting time… aaargh

When even Microsoft offers a 3d printable adapter plate too, to use the Surface Pro 3 (9.1mm thick) dock with a Surface Pro 4 (8.45mm thick), but then changing from an 0.2mm to an 0.3mm layer height, so it prints thinner (!) to fit your Surface Pro 5 (8.5mm thick)

Mounting the electronics on a rear panel, facing forwards, I only have ~73mm space, so while using DIN rails, I sought other cooling options, so three 60mm fans mounted at 90 degrees it is then ?

playing with pwm controller:

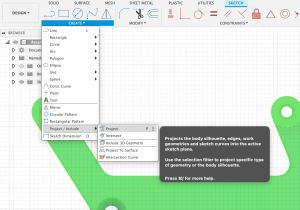

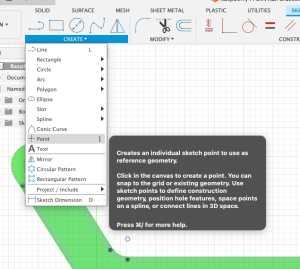

Fusion360 and 3d Printer, to make molds for routing panel corners: https://www.thingiverse.com/thing:4914457

New heater block (Slice Engineering Copperhead), heater cartridge (Sidewinder X1 64Watts 24V), thermistor (E3D PT1000), nozzle (Micro Swiss M2 Hardened High Speed Steel Nozzle) and fan (Sunon MF40202V2-A99-A), doing some test printing and tuning via https://teachingtechyt.github.io/calibration.html#flow