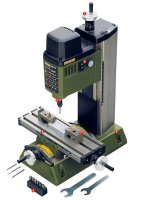

Sieg X2P Mini Mill Drill

• X2 mill with fixed column and large table

• Cast iron for vibration free running

• 500W variable speed motor

• Coarse down feed for drilling operations

• Fine down feed control for accurate tool height setting

The SIEG X2P is a 230-volt drilling/milling machine with a speed range of 100 to 2,500 rpm. It is powered by a 350 watt brush motor. The power is transmitted via a 2-stage gearbox. A shift lever is used to choose between the high and low speed ranges. The speed can be continuously regulated within the two speed ranges. Thanks to the reduction in the gearbox, the X2P has sufficient torque even in the low speed range. There is no quill installed in the X2P. The feed in the Z direction is carried out by moving the milling head using a quick adjustment with a star handle or using the fine feed that can be activated. Milling and drilling work can be carried out with repeatable accuracy using the adjustable depth stop on the Z-pillar. In relation to its size, the X2P has large travel distances in the X and Y axes. All guides can be adjusted without play using pressure strips. The speed controller, the operating light and the holder for the fine fuse are located on the front of the control unit. The emergency stop button and the fault light are located on the left side of the control unit.

Read more